Belwith Keeler: A Heritage of Hardware

When it comes to designing a space, pulls, handles, knobs and furniture hardware are the cherry on top — though often forgotten, these important details can dramatically change the look of a project. These utilitarian items are important accessories in the same way a diamond tennis bracelet or designer mules turn a little black dress into something truly special. Without the hardware, that beautiful wood bookcase you’ve specified is simply a box.

And few companies have worked on these critical elements as long as Belwith Keeler Decor Solutions, the Grand Rapids-based manufacturer who has been making pulls, handles and knobs since 1893, the year Grover Cleveland became president of the United States and Miner, Isaac and George Keeler founded Keeler Brass Co.

Keeler Brass, which would go on to become Belwith Keeler, grew along with the flourishing furniture industry in Grand Rapids.

“Understanding our history is something we leverage here,” said Knikki Grantham, creative director. “When we want to study historical references, we go out back (into the warehouse), not look in a book.”

When a company reaches the ripe old age of 130, it is bound to have gone through some times that tested it economically. Belwith Keeler is no different. Through the years it has evolved and done what was necessary to keep the company going, especially during tough times. It has changed hands and ownership, survived countless recessions (and two depressions) and yet it remains the standard for high-end hardware. It is currently owned by JVA Partners, a Chicago-based private investment firm.

It has outlasted two world wars and helped with both efforts, making products for military use during World War I and World War II, including the magazine for the M3A1 machine gun. It has also worked in markets beyond furniture. Keeler produced the hood ornament for the REO Royale in 1933 and the hood ornament for the 1964 Ford F-100 Truck. It also cast the iconic lion’s head belt buckle for Elvis Presley.

But it is the furnishings industry where Belwith Keeler has really shined and continues to be a leader. In fact, the company has been part of many iconic furniture designs including the custom “X” shaped handle created by furniture designer Paul Frankl for Brown Saltman Furniture. It works with some of the most iconic furniture companies in the world, including Stickley. And the company still does all of its design in-house today.

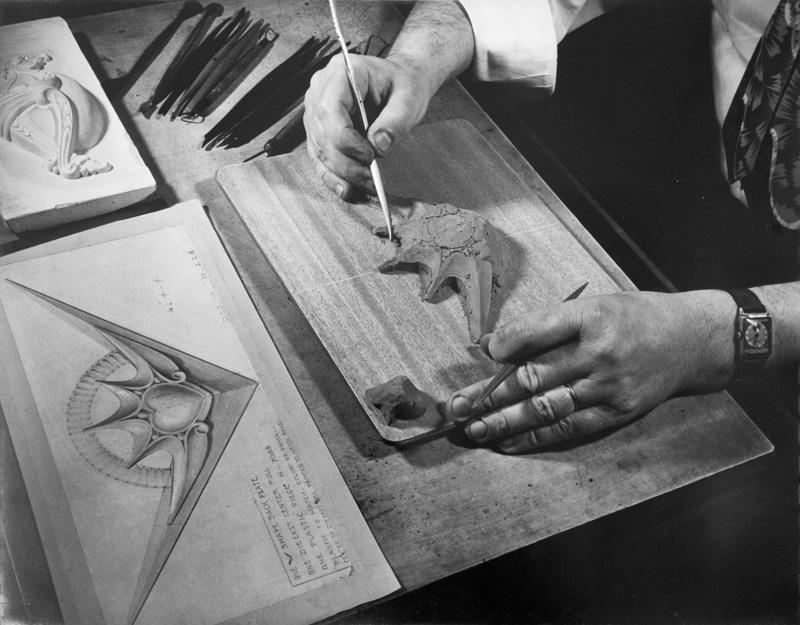

The company cares about its history in the furniture industry and maintains a living library containing hundreds of original drawings, images and internal documents that are archived in a corner of its Grand Rapids warehouse. It is an archived treasure trove of information about furniture hardware, including the original casts, hand-drawn sketches and design details from tens of thousands of products the company has created over its history.

And while you might think this archive is a quaint nod to the past, it is truly a living library. The company’s designers use it nearly every day. Today’s hardware design is informed by what the company has produced over its 130-year history.

Yet it is not satisfied with resting on past success. The company actively creates new products and designs, most of which launch at the Kitchen & Bath Industry Show. It recently launched several new collections at the KBIS, including its Bijou and Pebble collections. Pebble features pulls with organic, sculptural shapes. Belwith Keeler took a sensory approach with the tactile Pebble. It engages the sense of touch with its simple shapes, humble forms, smoothness and contours.

“There is something cathartic about the feel of a smooth stone in your hand, much like a worry stone,” said Grantham. “While the wellness trend is not new, the way we approach it is ever-evolving.”

Even after celebrating its 130th anniversary, Belwith Keeler believes its next 100 years will be lucrative if it continues to innovate. That includes expanding into different markets as well. The company recently began working with GE and its upscale Monogram Appliances brand to offer custom appliance hardware. Customers can choose colors and finishes to customize the look and feel of their appliances. It is the first time an after-market hardware maker has offered customizable pulls on appliances.

The company has products in just about every price category. It markets hardware direct to consumer through its Hickory Hardware brand. The Belwith Keeler brand serves the mid- to high-end market. And the company is relaunching its Keeler Brass brand to showcase its luxury hardware that is wholly designed in-house and made 100% in America. The company has factories in the U.S. and Asia and has a full staff in Asia, including quality control and purchasing.

To make it easy for designers, the brand launched its Anthology Series that allows for nearly limitless personalization. Designers can select a custom post and bar in a number of finishes to create more than 30,000 combinations that include textures and Edelman leather options in pulls and knobs. All hardware is available in standard sizes for cabinet pulls including 96-, 128-, 160-, 192-, and 224-millimeter and 12-inch center to center.

Belwith Keeler fully intends to be around to celebrate its 200th anniversary and beyond by continuing to hang its hat on what helped it survive and thrive through its first century — innovation and responding to the ever-changing market.